Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

The size grasp in the process of mechanical design is actually a manifestation of a person's design ability. If you do not have the corresponding design ability, the so -called size grasp is not good. So today I share a set of basic design processes and methods for everyone. Only a practical method can open up your road to perfect professional skills.

01 Determine the size of the outsourcing functional parts

At the beginning of any design, it should be based on the overall requirements of the scheme. First, confirm the models and specifications of some functional components for outsourcing. This can not only get the delivery period, cost and design size, but also basically evaluate you The solution is feasible, and one of the important things for structural design is the design size of outsourcing parts.

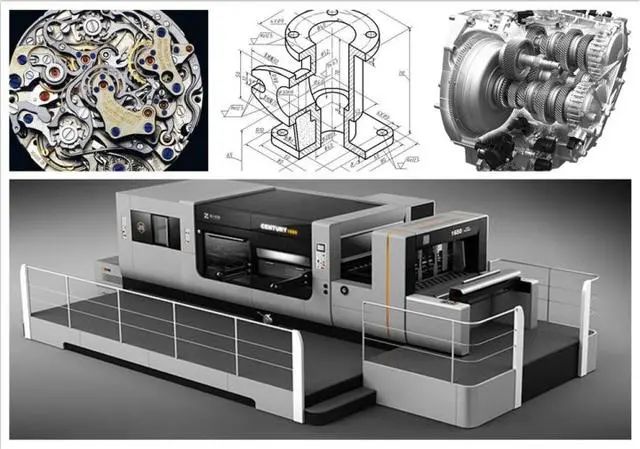

The so -called outsourcing functional parts, we can have a general understanding from the figure above. Of course, there are only a large number of types. I just use these to raise a chestnut. Product samples confirmed that the design size, some samples are paper, and some electronic samples increase the two -dimensional and three -dimensional drawings of parts (such as Japanese SMC pneumatic components, Chinese Adeke's pneumatic components, Japanese THK products wait).

As a design engineer, the first thing to do is based on the supplier's sample, and then draw the corresponding part structure based on the models and specifications you choose. This is your biggest design foundation, and this thing is basically not wrong or not or not. Will be changed (if this needs to be changed, it can only prove that your design scheme is wrong, and it has already started from the source).

For example, if we draw a complete processing map of a complete processing center, we should start drawing out of the screw, first draw the screw, then draw the shaft end, then draw the electric seat and the bearings, and then draw other related components (then other related components (then other related components (then other related components ( Of course, the premise is that you have confirmed the general structure, such as the itinerary, the shape of the machine, etc.). The design of many parts is buckled and one ring, one size influence and the other size. There is no randomness to give a size, each size is source and use.

Therefore, for a mechanical structure design engineer, it is a very important basic skill to have and familiar with the product sample of the product supporting supplier. This is also your most important resource and ability. It is the accumulation and maintenance of suppliers. This is a process of self -awakening and rise.

02 Confirm the design structure

In the processing of mechanical design structure, everyone has their own habits and ways of thinking. This is difficult to unify, but some traditional structure forms must have a good understanding and mastering. How to better deal with these connection methods. At the same time, when designing parts, not only should we consider the functional requirements of the parts, but also the needs of the parts processing process and the needs of assembly process. Wait, this is a very comprehensive ability.

A few days ago, I chatted with a friend. When it comes to a university teacher, I took a private job outside and helped others design a set of stamping molds. When testing the model, there was no problem with stamping molding. However, when I took parts, I couldn't find it. It turned out that the schedule of the mold opening was not enough, which was very embarrassing. This is where structural processing errors. The so -called structural processing must be a comprehensive evaluation and thinking based on product functions. Processing, assembly, debugging, production, and then after -sales need to spend it in your mind. Don't be lazy. If you don’t do this job, you will find that you will fall in any of the above environments. Very complete products will be beyond recognition by your last Dongpin and West, or even completely failed.

Where does the ability to deal with structural treatment come from? From watching more, drawing more, thinking more; from your project design experience, it comes from the mistakes you have made. Of course, what is more important is the guidance of a great teacher (a good teacher can let you let you make you Double the effort, he just dials you, you can save a few months of detour time), but good teachers can not be required, because others do not owe you, and more importantly as the workplace opponent, others want to see your jokes, others want to see your jokes. So this requires luck.

In fact, my suggestion is that if there is no good teacher in reality, then find drawings to copy, look and think, this is the most realistic shortcut. For a design engineer, imitation is definitely a shortcut of self -growth. At the beginning, I was thinking about innovation. As long as I can get the experience of their predecessors, it is already an extraordinary ability.

The confirmation of the design structure here refers to both the overall structure of the product and the structure of the parts of the product. This is basically confirmed during the design process of the assembly drawing. The reason for not many, because the comprehensive ability requires too high, it is not that you can master it for a few years.

03 Design part drawings (wall thickness)

After confirming the shape of the parts, how to confirm the wall thickness of the parts, this is a very confused thing for many people. The confirmation of the parts of the parts requires consideration, such as the shape of the parts, the material of the parts, the forming method of the parts. The heat treatment requirements of parts, the intensity of the use of parts, the location of the parts, etc. Only by considering all these comprehensive elements can we really design qualified parts drawings. Of course, this is not easy.

The design size of the drawing is used to confirm your parts design. This is the lowest error rate, because the wrong person to make the wrong person has basically committed it for you.

Many people who follow the pure academic routes suggest that you do mechanical analysis. Do not listen to them. Most parts do not need or it is impossible to do mechanical analysis. Otherwise, it will be expelled from you. The speed of transformation is to be fast and cost. If you do a mechanical analysis every time you design a part, then when you make this product, it is estimated that the daylily is cold, and the boss goes to the Northwest Wind.

When you have a certain design ability, you will slowly form your own design principles. What kind of structure would you give and what kind of materials do you correspond to what kind of requirements? The subconscious of the heart does not need to think about it at all. It is very natural.

In this matter, try to communicate as much as possible with those who have experienced a lot of research and development. Their abilities are exchanged for real gold and silver, and they can continue to use it with a bit of learning. And people in science and engineering have a kind of habit of "good teacher". As long as you ask for advice, you usually get a good result. Although it is difficult for them to pass their tricks to you, some basic design attempts, you can still use it from you. To identify and obtain in communication with them, this is the workplace you should go to the most.

There is an old saying in my hometown: the mouth is sweet and not folded, as long as the tongue rolls. Many times, the usefulness of the mouth is more useful than the diligence of hands and feet.

04 Confirm the standard parts

Like the outsourced parts mentioned earlier, the choice of standard parts is relatively easy, and once you choose the standard part, then it also confirms its structure and size accordingly. In the process of design, be sure Make full use of these parts that can easily confirm the structure and size. The more such parts, the more effective it is for your structural treatment.

And when selecting standard parts, its selection variables are relatively small. For example, we can confirm the selected models and specifications from the scope of force, assembly method, standard parts, standard parts, etc., and then based on The selected models and specifications are designed to design the corresponding drawings. In fact, in the current two -dimensional software and 3D software, there are standard parts libraries, so many graphics only need to be directly called. Cool things. Of course, to choose the standard parts, it is not really that there is no technical content, but it is slightly simpler than the design of the parts. If you still have no clue, then my suggestion is to learn from it. The road, you are at least not easy to fall into the pit, because the pit on the road is filled with your predecessors with your body.

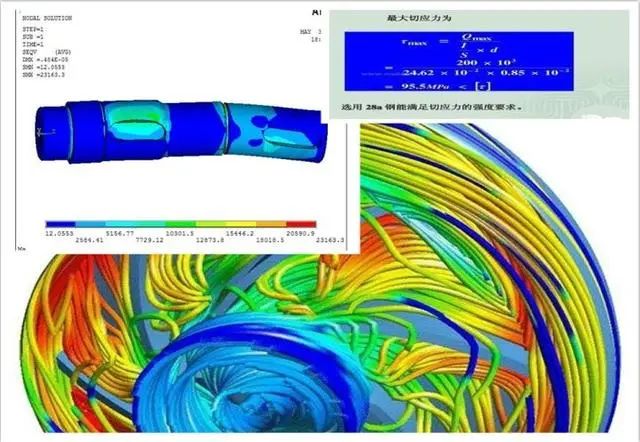

05 mechanics analysis

Although we have relatively few places to use mechanical analysis in the product design process of the enterprise, the place to do mechanical analysis still needs to be done. This is related to the quality and cost of the product. The province cannot be ignored at all.

There are many ways to analyze mechanical analysis. The old traditional way is to check the manual, set formula, and see the structure. Of course, the latest method is to use 3D design software for mechanical analysis. The perfect state of province ".

In summary, in fact, in the process of design, the most effective training is the analysis and explanation of drawings based on drawings. This is not replaced by any articles and methods. My habitual training method is to let the new people dismantle according to my requirements. Part of the component map, first follow their intentions, and then give it to me to check. I will list all the bad places in the design process, and then call him to tell him how to modify it. Then let him change the drawings based on my explanation, change the drawings before and give it to me for review. If there is still a problem, I will let him modify it again. After several rounds of product design, a newcomer will be a newcomer. It is basically a preliminary design consciousness, and then through a large number of product design projects to consolidate his design foundation, and gradually cultivate his own design style and principles, so that you can slowly let go.

To be honest, it is really not easy to cultivate a qualified design engineer, especially to cultivate a person with hard work. It is really a very tiring thing. Every time I do this, I tell myself that this person is a knife. I want to make him sharp and make him an indestructible weapon in the workplace, and you will get a little comfort every thought and this heart.

The content of the mechanical design is explained at the end, and you are welcome to add it.